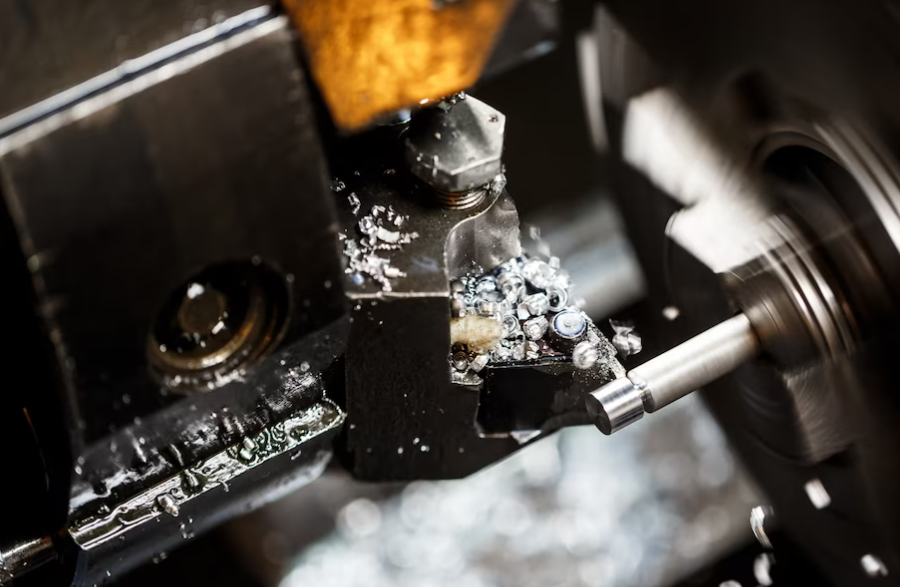

In the realm of manufacturing and engineering, precision is paramount. When it comes to machining tungsten carbide, a material known for its extreme hardness and durability, achieving precision can be a formidable challenge. However, with the right techniques and expertise, superior performance in tungsten carbide machining can be not only attainable but also highly efficient.

Understanding Tungsten Carbide

Before we delve into machining techniques, it’s crucial to understand what makes tungsten carbide unique. Tungsten carbide is a composite material comprised of tungsten and carbon atoms. It exhibits exceptional hardness, making it ideal for applications where wear resistance and durability are critical. Tungsten carbide is commonly used in cutting tools, drills, milling inserts, and a wide range of precision components.

Precision Tungsten Carbide Machining Methods

Machining tungsten carbide is not a one-size-fits-all endeavor. Different applications require specific techniques to achieve the desired precision and performance. Here are some key precision tungsten carbide machining methods:

1. Diamond Tooling

One of the most effective methods for machining tungsten carbide is using diamond tooling. Diamonds are the hardest natural material, and when bonded to cutting tools, they can efficiently remove material from tungsten carbide workpieces. Diamond tooling offers exceptional precision and can produce intricate geometries, making it ideal for complex machining tasks.

2. High-Speed Machining

High-speed machining involves using cutting tools with higher rotational speeds and feed rates. This technique reduces heat generation and improves chip evacuation, resulting in a smoother surface finish and extended tool life. When applied to tungsten carbide, high-speed machining can enhance precision and productivity.

3. Advanced Coolant Systems

Tungsten carbide machining generates a significant amount of heat, which can affect tool life and workpiece quality. Advanced coolant systems, such as through-tool coolant delivery and high-pressure coolant, help dissipate heat effectively. Proper cooling not only enhances precision but also prevents workpiece distortion.

Conclusion

Precision tungsten carbide machining is a critical aspect of modern manufacturing and engineering. To achieve superior performance, it’s essential to employ the right techniques and tools. Diamond tooling, high-speed machining, and advanced coolant systems are just a few of the methods that can unlock the full potential of tungsten carbide.